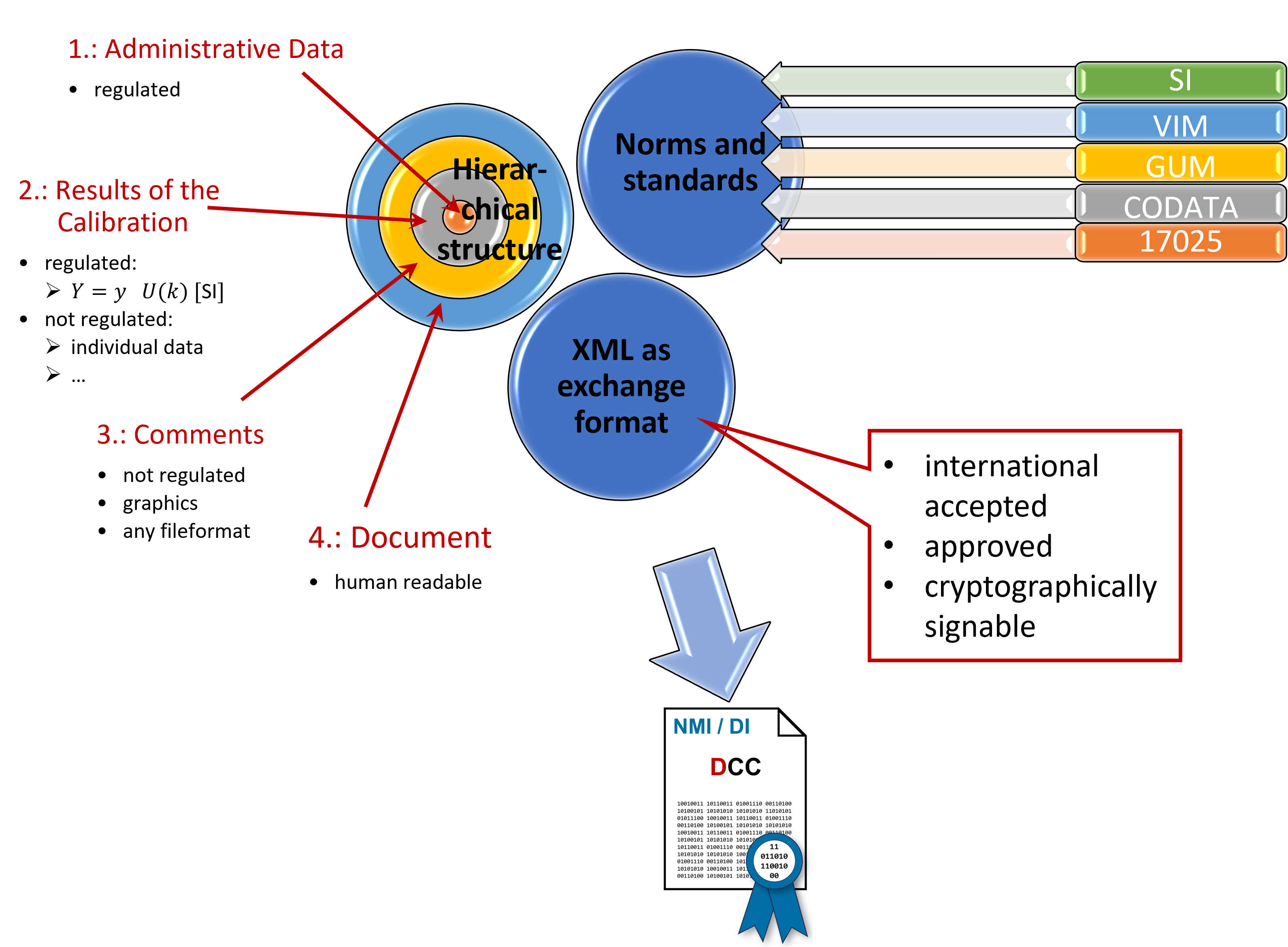

The digital calibration certificate (DCC) is the machine-readable counterpart of the previous calibration certificate. Its basic structure is shown in Figure 1. It has a hierarchical structure and consists of regulated areas, whose information must meet certain requirements, and non-regulated areas, in which more liberal information is possible. The DCC is created in Extensible Markup Language (XML), which has become the internationally accepted data exchange format.

Figure 1: Basic structure of the digital calibration certificate (DCC). Like the previous calibration certificate, it also provides information about the quality of a result that can be achieved with an instrument. The traceable calibration of instruments is therefore the essential pillar for correct and comparable measurement, as is indispensable in industrial production, among other things. Without it, it is not possible to make statements about the quality of a product. The special added value of the DK results from its machine readability. This means that all the information it contains, including the numerical calibration curves, can be transferred directly and automatically to all digitally supported processes.

Due to the machine readability of the DCC, digitally supported processes in particular (e.g. in production and quality assurance) benefit enormously. For example, automatic reconciliation of data from different calibration certificates can be integrated into the complex process of a production chain. In this way, it will be possible to optimally control processes in the future according to the framework conditions specified in the DCC. For example, when specifying a length, which is important in all industrial sectors, the use of gauge blocks depends on the temperature. With the information from the calibration certificate on the permitted temperature (e.g. 20 °C ± 1 °C) and the specification of the temperature-dependent length veining (e.g. for steel 11 µm/(K∙m)), conclusions can be drawn directly about the manufacturing accuracy.